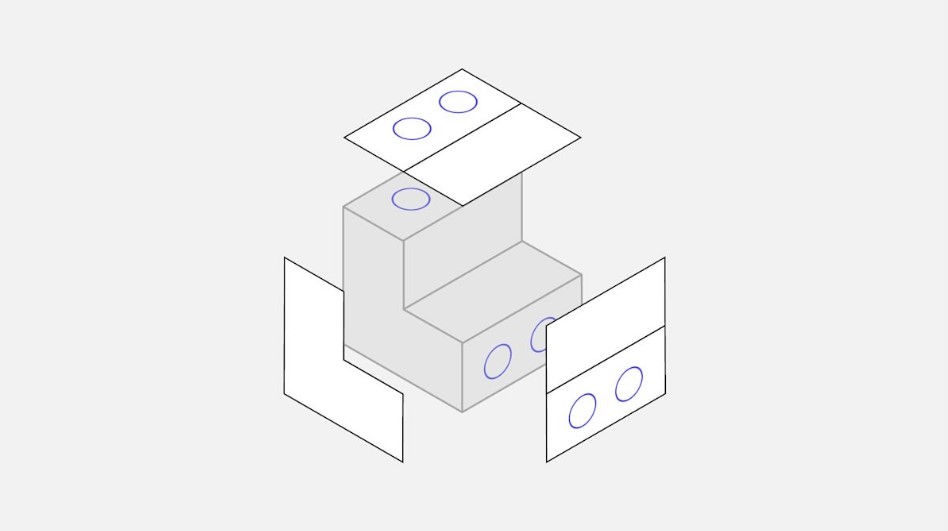

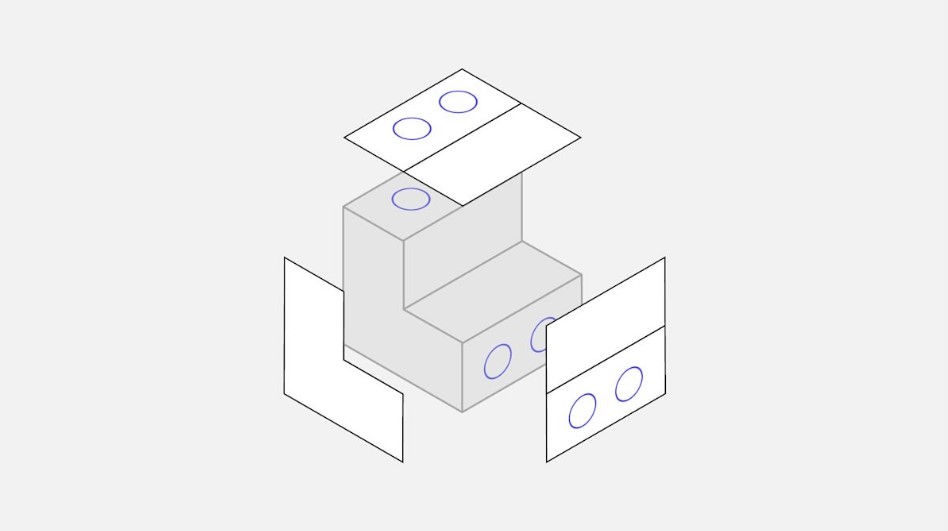

الوصول إلى الأداة هو أحد قيود التصميم الرئيسية في تصنيع CNC. للوصول إلى جميع أسطح النموذج ، يجب تدوير قطعة العمل عدة مرات.

كلما تم تدوير قطعة العمل ، يجب إعادة معايرة الجهاز ويجب تحديد نظام إحداثيات جديد.

أثناء التصميم ، من المهم النظر في إعدادات الماكينة لسببين:

-

يؤثر إجمالي عدد إعدادات الماكينة على التكلفة. يتطلب الدوران وإعادة تنظيم الجزء العمل اليدوي ويزيد من وقت التصنيع. غالبًا ما يكون هذا مقبولًا إذا احتاج الجزء إلى تدوير ما يصل إلى ثلاث أو أربع مرات ، ولكن أي شيء أعلى من هذا الحد مفرط.

-

لتحقيق أقصى دقة الموضعية النسبية ، يجب تشكيل ميزتين في نفس الإعداد. وذلك لأن خطوة المعايرة الجديدة تقدم خطأ صغير (ولكن غير مؤهل).

ما هو 5 محور CNC الآلات?

A تقوم آلة CNC بحجم 5 محاور بتحريك أدوات القطع أو الأجزاء على طول خمسة محاور في نفس الوقت. Multi-Axis CNC Machining يمكن تصنيع الأجزاء ذات الأشكال الهندسية المعقدة ، لأنها توفر محورين إضافيين. هذه الآلات تلغي الحاجة إلى إعدادات الماكينة المتعددة.

ما هي مزايا وقيود تصنيع CNC 5 محاور؟

يتيح تصنيع CNC من خمسة محاور للأداة أن تظل عرضية باستمرار سطح القطع. يمكن أن تكون مسارات الأدوات أكثر تعقيدًا وفعالية ، مما يؤدي إلى أجزاء ذات الانتهاء من السطح بشكل أفضل وأوقات تصنيع أقل.

ومع ذلك ، فإن CNC 5 محاور لها حدودها. لا تزال قيود هندسة الأدوات الأساسية وقيود الوصول إلى الأدوات تنطبق (على سبيل المثال ، لا يمكن تشكيل الأجزاء ذات الأشكال الهندسية الداخلية). علاوة على ذلك ، فإن تكلفة استخدام هذه الأنظمة أعلى.

MICHINING CNC

تعتبر عمليات التقويض ميزات لا يمكن تشكيلها باستخدام أدوات القطع القياسية ، حيث لا يمكن الوصول إلى بعض أسطحها مباشرة من الأعلى.

هناك نوعان رئيسيان من عمليات التقويض: T-slots وتوازات. يمكن أن تكون عمليات التقويض أحادية الجانب أو على الوجهين ويتم تشكيلها باستخدام أدوات خاصة.

أدوات القطع الفاصلة مصنوعة من أ شفرة القطع الأفقية تعلق على رمح عمودي. يمكن أن يختلف عرض Undercut بين 3 مم و 40 ملم. نوصي باستخدام أحجام قياسية للعرض (أي زيادات ملليمتر كاملة أو كسور بوصة قياسية) ، لأنه من المرجح أن تكون أداة مناسبة متوفرة بالفعل.

لتوابل أدوات القطع، الزاوية هي حجم الميزة المحددة. تعتبر كل من أدوات توابل 45 و 60 درجة قياسية. توجد أيضًا أدوات بزاوية 5 و 10 و 10 و 120 درجة (بزيادات 10 درجات) ولكنها أقل استخدامًا بشكل شائع.

اشترك في النشرة الإخبارية لدينا

اشترك في النشرة الإخبارية لدينا