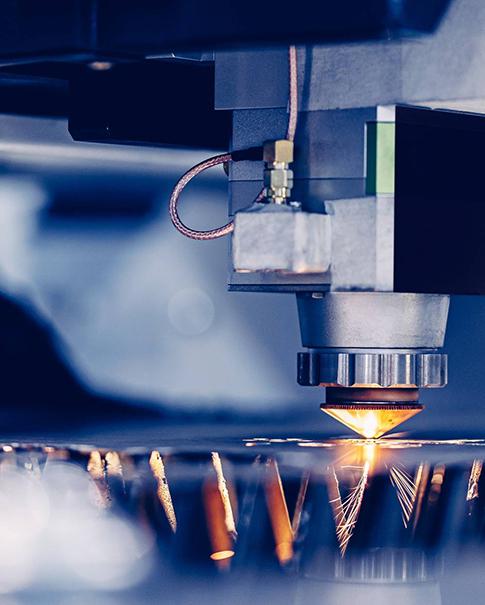

في عالم التصنيع باستخدام الحاسب الآلي والتحويلأداة القطع هي سيف الفارس. يُعد اختيار مادة أداة القطع المناسبة من أهم القرارات لتحسين كفاءة الإنتاج وخفض التكاليف وتحسين جودة القطع. إذا استخدمت أداة غير مناسبة، فستواجه مشاكل متكررة مثل تشقق الأداة، وسوء تشطيب السطح، وانخفاض الإنتاجية.

سوف يرشدك هذا الدليل خلال المواد الرئيسية لأدوات القطع ويوفر إطارًا واضحًا لمساعدتك في اتخاذ أفضل خيار بناءً على مهمة المعالجة.

لماذا تعتبر مادة أدوات القطع مهمة جدًا؟

تُولّد عملية القطع حرارةً وضغطًا عاليين للغاية. يجب أن تقاوم مادة الأداة ما يلي:

· مقاومة التآكل: تمنع التآكل بسبب الرقائق وتحافظ على الحدة.

· الصلابة: يجب أن تكون أكثر صلابة من المادة التي تتم معالجتها، وخاصة في درجات الحرارة العالية (يشار إليها باسم "الصلابة الحمراء").

· المتانة (الصلابة): يمكنها تحمل الصدمات وقوى القطع المتقطعة، مما يمنع التقطيع والكسر.

· الصلابة الساخنة: القدرة على الحفاظ على الصلابة في درجات الحرارة العالية الناتجة أثناء القطع.

لا يمكن لأي مادة أن تكون مثالية في جميع جوانبها. تهدف عملية الاختيار إلى إيجاد أفضل توازن بين هذه السمات لمعالجة تحديات المعالجة المحددة.

شرح مفصل لمواد أداة القطع الرئيسية

فيما يلي أكثر أنواع مواد أدوات القطع استخدامًا اليوم، مرتبة من الأكثر عمومية إلى الأكثر تخصصًا.

الفولاذ عالي السرعة (HSS)

ما هو: هو فولاذ أداة عالي الجودة مصنوع من خلال إضافة عناصر مثل التنغستن والموليبدينوم والكروم والفاناديوم.

· المزايا: صلابة ممتازة، تكلفة منخفضة، قادرة على تصنيع أشكال أدوات معقدة للغاية (مثل المثاقب، الصنابير، المثاقب)، وسهلة إعادة الطحن.

· العيوب: مقاومة ضعيفة للتآكل والصلابة الحرارية (تليين عند حوالي 600 درجة مئوية)، وسرعة القطع أقل بكثير من سرعة الكربيد الأسمنتي.

· أفضل التطبيقات: التشغيل بسرعة منخفضة، والقطع المتقطع، والأدوات ذات الهندسة المعقدة، ومعالجة المعادن غير الحديدية، وورش الإصلاح، والإنتاج على دفعات صغيرة.

2. الكربيد

ما هو: يُلبَّد بتقنية مسحوق المعادن باستخدام جزيئات كربيد التنغستن (WC) ومادة رابطة من الكوبالت (Co). يُعطي كربيد التنغستن الصلابة، بينما يُعطي الكوبالت المتانة. تُعدّ هذه المادة القوة الرئيسية المُطلقة في ماكينات التحكم الرقمي الحديثة.

المزايا: يتميز بمقاومة ممتازة للتآكل وصلابة حرارية (تصل إلى 1000 درجة مئوية)، وسرعة قطع أعلى من سرعة قطع الفولاذ عالي السرعة (HSS) بمرتين إلى ثلاث مرات. كما يتميز بتعدد استخدامات فائق.

· العيوب: أكثر هشاشة من الفولاذ عالي السرعة وأكثر تكلفة.

أفضل التطبيقات: من نصف التشطيب إلى التشطيب النهائي لمعظم المواد، من الفولاذ والفولاذ المقاوم للصدأ إلى الحديد الزهر والسبائك الفائقة. (ملاحظة: يُعد كربيد الأسمنت بحد ذاته فئة واسعة، ويمكن أن يخضع أداؤه لتغيرات كبيرة من خلال تعديلات الطلاء والتركيب.)

3. كربيد مطلي

ما هو: يتم ترسيب فيلم من مادة فائقة الصلابة رقيقة للغاية (بضعة ميكرومترات) على ركيزة من سبيكة صلبة من خلال عمليات CVD (الترسيب الكيميائي للبخار) أو PVD (الترسيب الفيزيائي للبخار).

· الطلاءات الشائعة:

· نتريد التيتانيوم (TiN): طلاء ذهبي عالمي يعزز مقاومة التآكل.

· نتريد التيتانيوم (TiCN): أكثر مقاومة للتآكل من TiN، أزرق أو رمادي.

نتريد التيتانيوم والألومنيوم (TiAlN)/نتريد الكروم والألومنيوم (AlCrN): طلاء عالي الجودة. عند درجات حرارة القطع العالية، تتشكل طبقة من الألومينا، تتميز بصلابة حرارية عالية ومقاومة للأكسدة، مما يجعلها مناسبة جدًا للتشغيل الآلي عالي السرعة والقطع الجاف.

· المزايا: يعمل الطلاء على تعزيز صلابة السطح وأداء الحاجز الحراري والقدرة على التشحيم بشكل كبير، مما يزيد من عمر الأداة عدة مرات.

أفضل التطبيقات: يُغطي تقريبًا جميع سيناريوهات المعالجة، ويعتمد الاختيار على المادة المُعالجة. يُعد TiAlN خيارًا ممتازًا لمعالجة الفولاذ والحديد الزهر.

4. السيراميك

ما هو: يتم تقسيمه بشكل أساسي إلى فئتين: القائم على الألومينا (Al2O3) (يستخدم في معالجة الحديد الزهر عالي السرعة) والقائم على نترات السيليكون (Si3N4) (يستخدم في التشغيل الخشن عالي السرعة للحديد الزهر).

· المزايا: يتمتع بصلابة حرارية ومقاومة للتآكل أعلى من كربيد الأسمنت، واستقرار كيميائي جيد، وسرعة قطع عالية للغاية.

· العيوب: هشة للغاية، ضعيفة التحمل للصدمات والقطع المتقطع، وغير مناسبة للمواد اللزجة مثل الألومنيوم.

· أفضل التطبيقات: التشطيب عالي السرعة والقطع الجاف للحديد الزهر والسبائك الفائقة.

5. نتريد البورون المكعب (CBN)

ما هو: مادة صناعية ذات صلابة لا تضاهيها صلابة الماس. تُباع عادةً على شكل رؤوس CBN صغيرة ملحومة على حشوات من سبائك صلبة.

· المزايا: صلابة عالية للغاية واستقرار حراري، مما يجعلها مناسبة للغاية لتقوية الفولاذ والحديد الزهر المبرد.

· العيوب: التكلفة مرتفعة للغاية والمتانة متوسطة.

أفضل استخدام: تشطيب الفولاذ المُخمَّد ذو صلابة أعلى من 45HRC (مثل فولاذ القوالب والتروس). يُعد الخيار الأمثل للخراطة بدلاً من عملية الطحن.

6. الماس متعدد البلورات (PCD)

ما هو: يتم تصنيعه عن طريق تلبيد جزيئات الماس الاصطناعي في درجة حرارة عالية وضغط مرتفع، وعادة ما يتم لحامه أيضًا على ركيزة من سبيكة صلبة.

· المزايا: أقوى وأكثر مواد القطع مقاومة للتآكل المتوفرة اليوم.

· العيوب: إنها باهظة الثمن للغاية، وهشة للغاية، ويمكن أن تخضع لتفاعلات كيميائية مع المواد القائمة على الحديد (الفولاذ، والحديد الزهر) (سوف ينتشر الكربون عند 800 درجة مئوية)، لذلك لا يمكن استخدامها في معالجة المعادن الحديدية.

· أفضل تطبيق: معالجة عالية السرعة وعالية الدقة للمعادن غير الحديدية والمواد الكاشطة (الكاشطة)، مثل سبائك السيليكون والألومنيوم، والمواد المركبة، وألياف الكربون، والبلاستيك، والنحاس، وسبائك الألومنيوم عالية السيليكون.

كيفية الاختيار: مخطط انسيابي للقرار والعوامل الرئيسية

عند اختيار مواد الأدوات لتطبيقك، يرجى التفكير بالترتيب التالي:

1. مادة قطعة العمل التي سيتم معالجتها (مادة قطعة العمل) - هذا هو العامل الأساسي!

الألومنيوم، النحاس، المواد المركبة، إلخ: يُعدّ كربيد الأسمنت غير المطلي الخيار الأمثل للسرعة العالية والجودة العالية وعمر الخدمة الطويل. يُعدّ كربيد الأسمنت غير المطلي خيارًا اقتصاديًا.

الفولاذ الكربوني، الفولاذ السبائكي، الفولاذ المقاوم للصدأ: يُعدّ كربيد الأسمنت المطلي (TiAlN/AlCrN) خيارًا عالميًا. بالنسبة لأدوات القطع منخفضة السرعة أو المعقدة، لا يزال الفولاذ عالي السرعة (HSS) خيارًا مناسبًا. أما بالنسبة للفولاذ المُخمّد والمُصلّب (>45HRC)، فيُفضّل استخدام CBN.

الحديد الزهر: سبيكة صلبة مطلية فعّالة جدًا. للمعالجة عالية السرعة، يُعدّ السيراميك خيارًا مثاليًا.

سبائك عالية الحرارة (مثل سبيكة Inconel وسبائك التيتانيوم): يلزم استخدام أنواع خاصة من السبائك الصلبة ذات طبقات طلاء متينة خاصة (مثل AlCrN). كما يمكن استخدام السيراميك وCBN.

غير معدني (بلاستيك، خشب، إلخ): عادةً ما يكفي استخدام سبيكة صلبة غير مطلية أو HSS. بالنسبة للبلاستيك المقوى ذي المقاومة العالية للتآكل، يتميز PCD بأطول عمر افتراضي.

2. نوع عملية المعالجة

· التشغيل الخشن مقابل التشغيل النهائي: يتطلب التشغيل الخشن الصلابة (اختر درجة سبيكة صلبة ذات صلابة أفضل)، بينما تعطي التشغيل النهائي الأولوية لمقاومة التآكل والصلابة (اختر درجة أكثر صلابة أو CBN/PCD).

القطع المستمر مقابل القطع المتقطع: عادةً ما يكون الطحن متقطعًا ويتطلب صلابة عالية (سبائك صلبة أو فولاذ عالي السرعة). عادةً ما يكون تدوير الدائرة الخارجية مستمرًا، ويمكن استخدام مواد أكثر صلابة وهشاشة (مثل السيراميك).

3. أدوات الماكينة والإعداد

تكون أدوات الماكينة القديمة أو الإعدادات ذات الصلابة غير الكافية عرضة للاهتزاز وتتطلب أدوات ذات صلابة أفضل (مثل كربيد الأسمنت القوي أو HSS).

السرعة العالية والصلابة العالية الحديثة أدوات آلية CNC يمكن الاستفادة بشكل كامل من أداء السيراميك وكربيدات الأسمنت المطلية.

4. اعتبارات التكلفة

· التكلفة الأولية مقابل تكلفة الوحدة: على الرغم من أن شفرات CBN وPCD باهظة الثمن، إلا أنها في الإنتاج الضخم، نظرًا لعمر الخدمة الطويل للغاية وكفاءة المعالجة العالية للغاية، يمكنها تقليل تكلفة معالجة كل جزء بشكل كبير.

· إنتاج نماذج أولية بكميات صغيرة: يوفر كربيد الأسمنت المطلي أفضل تنوع وتوازن في القيمة. يبقى الفولاذ عالي السرعة فعالاً من حيث التكلفة للأشكال المعقدة للغاية أو كميات العمل الصغيرة جدًا.

اشترك في النشرة الإخبارية لدينا

اشترك في النشرة الإخبارية لدينا